© Shell International Ltd

Research & Development / Intellectual Property Development

Here we are committed to taking innovative technological concepts, developing them into a practical and economically viable state, and creating commercially successful ventures using the technologies.

With particular specialisations in control & automation and sub-sea & offshore engineering, STL is ideally placed to take innovative & cutting-edge sub-sea and offshore technology IP from its infancy, to eventual IPO or trade sale.

If you would like further information or are interested in our services, please contact us here.

.

Case Studies

Neptune – Offshore Access System

The Challenge

To transfer personnel and equipment between an offshore support vessel and a fixed structure (wind turbine or hydrocarbons production facility) quickly and safely. The design is based on a 56 metre DP Support vessel and is intended to be able to operate in up to at least a significant wave height (Hs) of 2.5 metres (which may contain a wave of 4.65 metres). Larger vessels will have a greater operational range depending on the particular vessels’ response to wave actions.

Analysis

The system is space stabilised in 6 degrees of freedom (DoF – roll, pitch, yaw, heave, surge, sway) and will allow safe transfers from a vessel to and from a fixed structure in marginal sea states.Neptune is designed to reach at least 28 metres above lowest astronomical tide and maintain a standoff of at least 15 metres from the vessel to the target structure. It will carry a payload of 500 kg and will have secure seating for 4 persons or 3 including a stretchered medical evacuation. With the personnel carrier removed Neptune will have a lift capacity of at least 1,000 kg. The system is fully redundant and has a built in self stowing ability in the event of a complete system failure.To assist in the development of Neptune a 6 DoF vessel motion simulator (a Stewart platform) has been built and is currently being used in conjunction with a scaled model (approximately 6 metres high) to finalise the design and assist in the development of the mechanical/hydraulic/control systems, and also carry out failure mode test investigations.

Solution

The Neptune system is shown below is fitted to the stern quarter of an 56 metre Wind Turbine Support Vessel. It is expected that the support vessel will be equipped with sufficient accommodation facilities to support the marine crew in addition to all additional crew members working 24hours/day involved in the tasks of maintaining the field production equipment. It will be equipped with workshops, instrument shops and storage facilities.

.

Stewart Table / Motion Platform

The Challenge

To create a device capable of simulating vessel motion, in order to test the control system of the Neptune Offshore Access system described in Challenge 1 The device must be capable of achieving a maximum heave of 2.5m and pitch and roll of ± 15°.

Analysis

Inspiration was sought from existing motion simulators and in particular The Stewart Table which is a 6 degree of freedom hexapod system.

Consultation with ‘H Technologies’ in Littlehampton was sought for the design of the motion table in accordance with the data obtained from the analysis of vessel motions.

Solution

The simulator is now fully operational and an image of it is given below, the system is capable of replicating the motions of a relatively small vessel (53 metres long) to a scale of one eighth full size in a significant wave height seas (Hs) of 2.5 metres (Hmax = Hs x 1.86).

| Degree of Freedom | Limit of Actuator | Safe Working Stroke |

| Heave | 481.44 (+/-mm) | 419.06 (+/-mm) |

| Surge | 1004.72 (+/-mm) | 879.13 (+/-mm) |

| Sway | 909.09 (+/-mm) | 801.20 (+/-mm) |

| Pitch | 36.560 | 30.860 |

| Roll | 33.680 | 29.580 |

| Yaw | 45.860 | 38.900 |

.

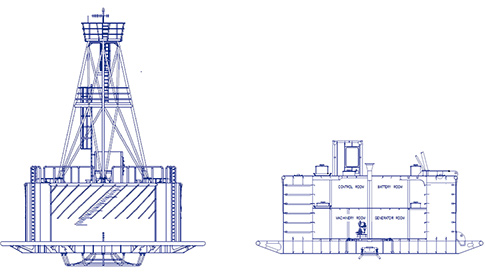

WellBuoy

The Challenge

The design of Wellbuoy is the result of a FEED contract placed on STL/Oceantech by a major E&P North sea operator to minimise sub sea step out from a host gas production platform and to provide a method of control, supervision and chemical injection that is simple to construct and install and economic to maintain and supply. No electro/hydraulic/chemical armoured umbilical connecting Wellbuoy to the host facility is required.

The original design was based on a remote gas reserve in 90 metres water depth some 20 kilometres from the host platform. An autonomy of 90 days is required with an expected field life of 4 years.

The system can be easily reused at other locations a number of times.

Analysis

Focus was on achieving the main functionality of the system whilst providing reduced capital and running costs, as detailed below:

1. Control and monitoring of wellhead functions, chemical injection, valve control, monitoring and sensor monitoring.

2. Remote operation from a distant master station and real-time communications for monitoring and control.

3. Autonomy in responding to locally-detected conditions; for example causing ESD.

4. Reliability to function for long periods without maintenance; fully-flexible, dual- redundant configuration deployed for all critical equipment to ensure availability is maintained in the case of equipment failure.

5. Maintainability to minimise manned intervention requirements in view of the restrictions on boarding likely to occur due to adverse weather conditions.

6. Reuseable to new location on field depletion.

Solution

Using proven single point mooring system technology, coupled with a reduced maintenance system, to design a buoy of modular design, as illustrated below:

.

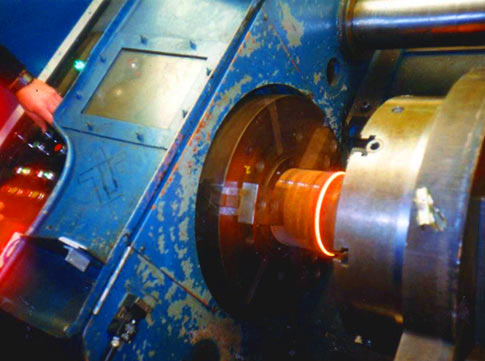

Friction Welding

The Challenge

To investigate the possibility of developing a system capable of welding small diameter (maximum OD 250mm) pipes together to form a continuous pipeline. The system must be extremely reliable, fast and produce high quality welds. It must be fully automatic, use minimal personnel and incorporate an automated weld inspection process.

Analysis

Friction welding has been and is still widely used in various industrial applications to form a high strength, high quality joint during a manufacturing process. It has also applications in the civil and subsea offshore engineering industries to form shear stud and bolted structural connections.

Various target markets have been identified including servicing reel type pipeline lay barges where long pipeline assembly sites are unavailable, offshore pipeline assembly/installation using a suitably equipped support vessel.Total costs will be significantly reduced by a reduction in vessel size and anchor handling support, reduced requirement for specialist personnel, faster production rates, etc.

Solution

Whilst the term friction welding is generally used to describe the process it is in fact better described as a forging process. No other materials are added and the weld preparation is limited to a clean cut only, with any impurities carried away on initial contact between the two surfaces.

STL have carried out a number of test welds using 200mm OD pipeline donated to the project by a major UK North Sea operation company. Sections taken from these welds have been subjected to a full range of mechanical and metallurgical tests by the mechanical engineering department of a well known university and were found to be extremely satisfactory in terms of quality and repeatability.

Each trial weld was completed in less than 30 seconds although to provide a usable system it will be necessary to develop a method of cleaning the upset material on both the inside and outside of the welded pipe.

Existing industrial machinery can be converted to carry out the weld avoiding the cost of designing and developing a purpose made machine although additional equipment will need to be developed to clean, inspect and protect the weld.